Sewage Treatment plant is a facility that treats domestic sewer to remove contaminants, making it safe for discharge or reuse. It as multi stage process, including physical, chemical and biological treatments to removes contaminants.

MBBR, SBR and MBR are the advanced Technologies aim to improve water quality, reduce energy consumption and make treatment efficient and sustainable.

Water Treatment plant removes Suspended Solids, Colour and odour. The Water treatment process involves several stages generally Filtration, Disinfection, Storage and Distribution.

We supply Water filtration plant depends upon the various capacity and specific filtration range from smaller to Larger Capacity. MoC MSFRP, MSEP, MSRL

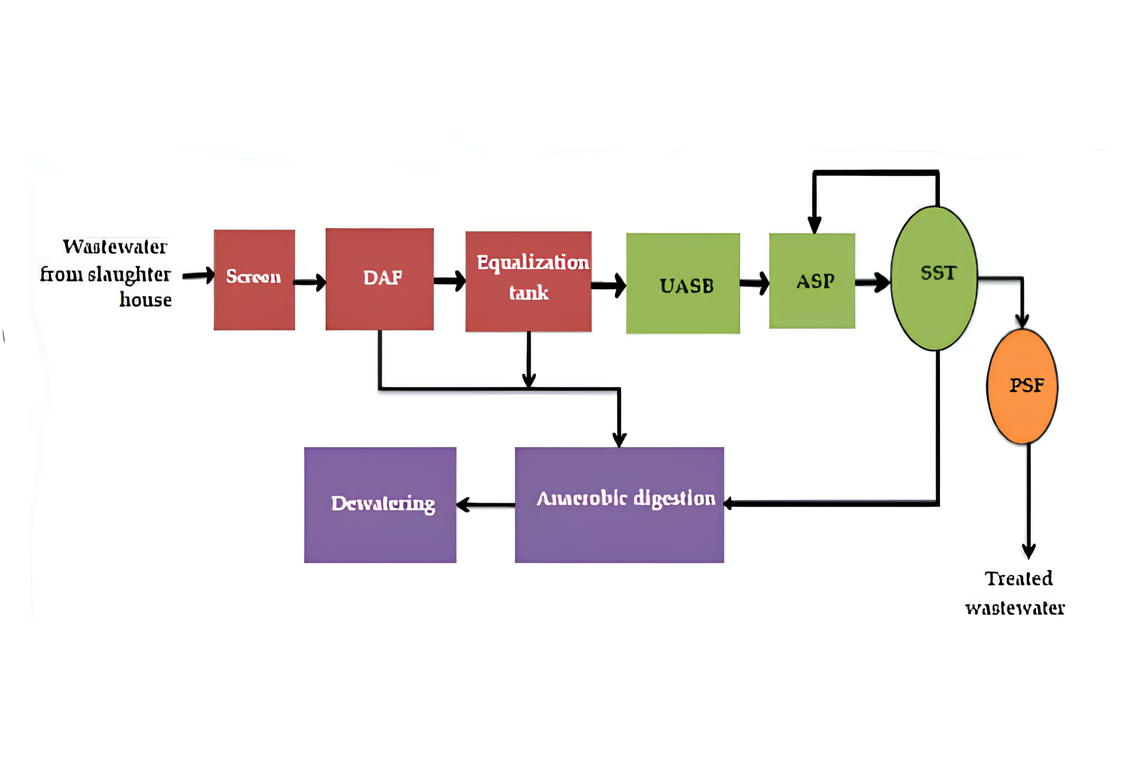

Effluent treatment plant treats industrial effluents which often contain chemicals, heavy metals and other hazardous materials. removes pollutants from wastewater, making it safe for discharge or reuse.

It involves a series process, Screening and Pre-treatment, Physical treatment, Chemical treatment, Biological treatment, Disinfection, Polishing Treatment and Discharge or reuse.

A RO plant removes sediment and chlorine from water with a pre filter before it forces water through a semipermeable membrane to remove dissolved solids.

Dewatering can be done with the help of presses or centrifuges (mechanical dewatering), Filtration (Filter Bags) or Physical processes in drying beds.

Mechanical dewatering and filtration often require the use of chemicals (coagulation and flocculants) to enhance the process.

An UF plant uses membrane filtration to separate particles and solutes from a liquid. This process removes suspended solids, bacteria, viruses and other contaminants, resulting in high-purity water.

Water softening plant uses ion exchange to exchange calcium and magnesium ions with neutral sodium ions, softening the water to a desired hardness.

The Iron Removal filters are designed to remove the excess iron content present in the feed water. The working principal of most iron filtration systems operate on oxidizing the iron (Oxidation) to convert it form a ferrous (dissolved or soluble) to a ferric or undissolved state. There are several methods for removal of iron from feed water like ion exchange and water softening. Limestone treatment. Oxidation by aeration, chlorination, ozonation followed by Filtration.

A bio septic tank is a waterproof chamber where bacteria break down organic waste form wastewater without oxygen through anaerobic digestion. For a durable and long-lasting septic tank, a concrete tank is generally considered the best option. Concrete tanks are more resistant to damage from soil movement and offer excellent durability, plastic tanks are lighter and easier to install.

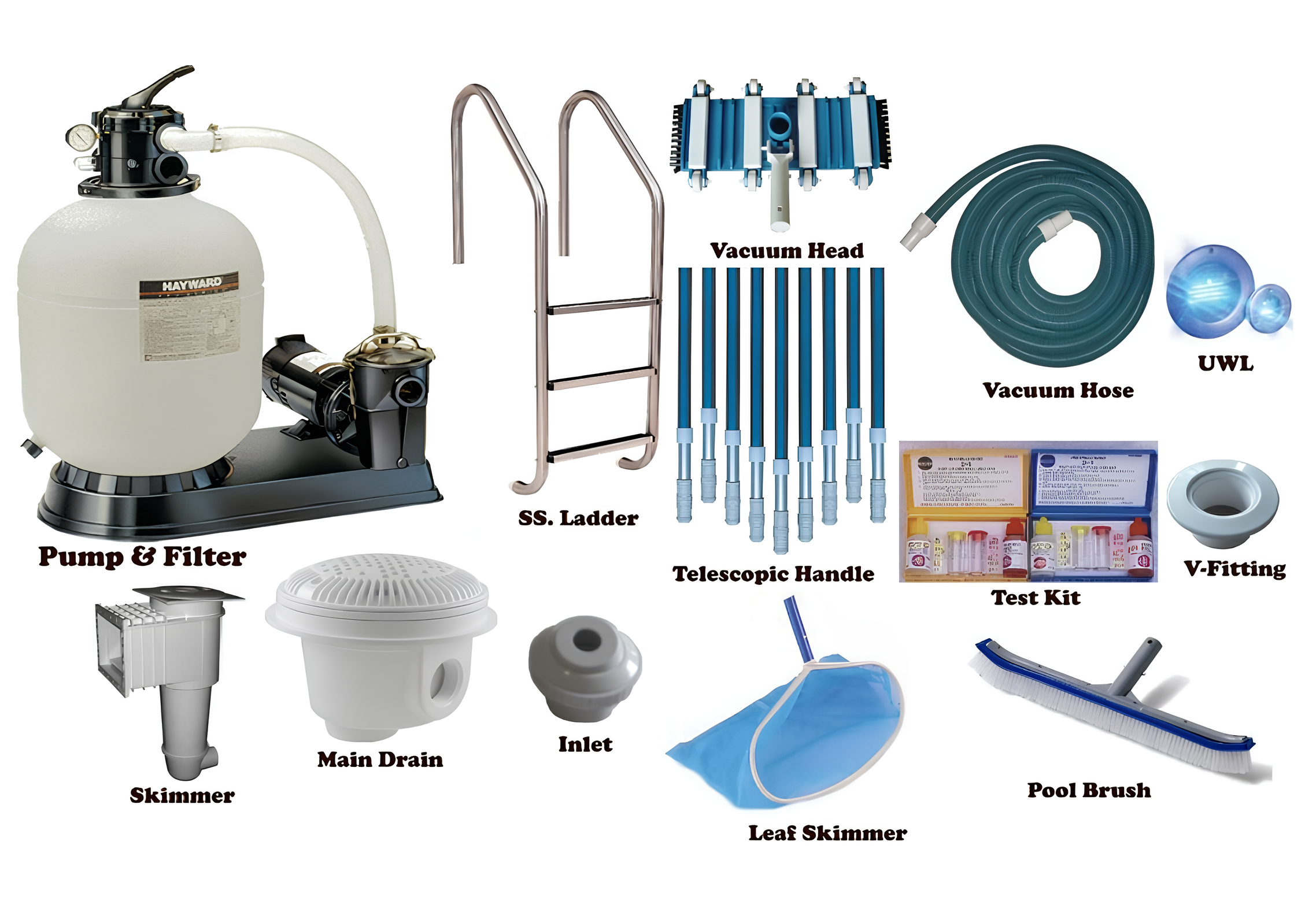

The purpose of swimming pool filtration is to clarify the water, which contains suspended particles, by passing it through a filter. It also prevents the growth of algae. Types of swimming pools are classified by their location. Lap Pool, Leisure Pools and Competition Pools. Types of swimming pools Based on construction materials. Concrete Pools, Fiberglass Pools and Vinyl Liner Pools. We provide customized swimming pool based the location.

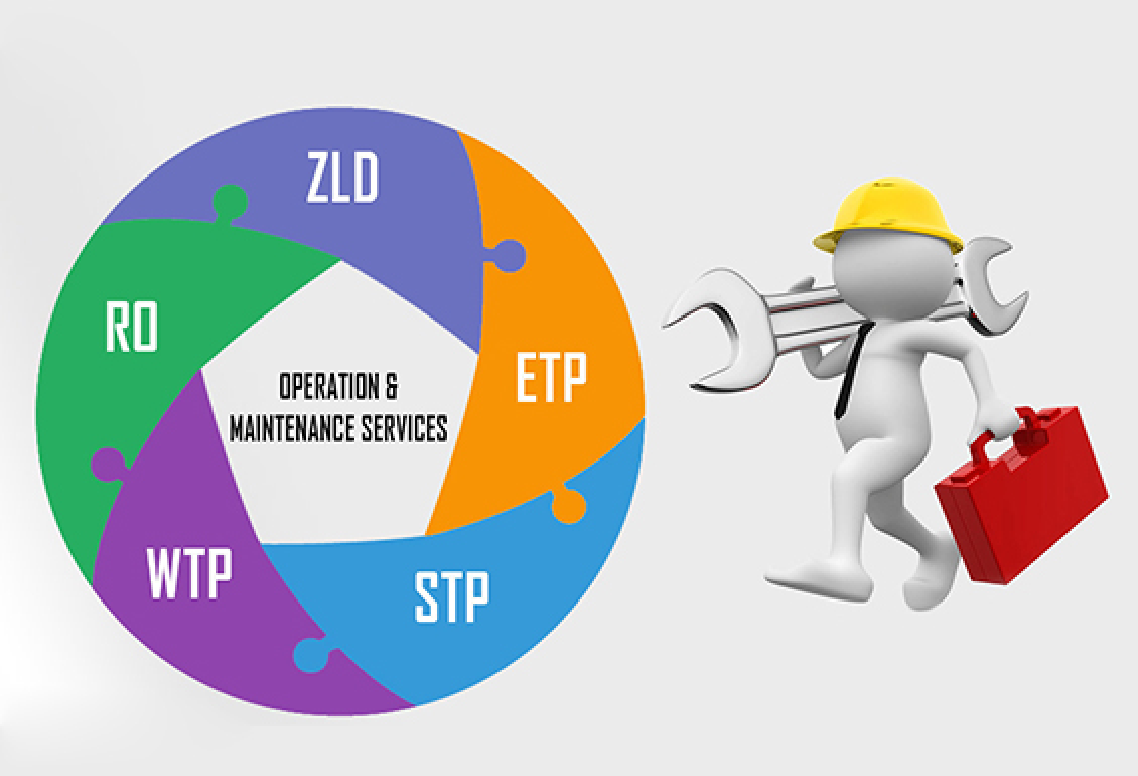

Annual Maintenance Contract (AMC): The maintenance services can include regular inspection, preventive maintenance, and repair services for a set period, typically one year.

Comprehensive AMC: The comprehensive AMC covers all preventive maintenance and corrective maintenance costs, including parts and labor.

Operation and Maintenance (O&M): This included both the operational aspects, like day to day activities and procedures needed to keep a system, facility or equipment effectively and reliably throughout its life cycle.